Description

The wheel profile measuring equipment is divided into three separate systems:

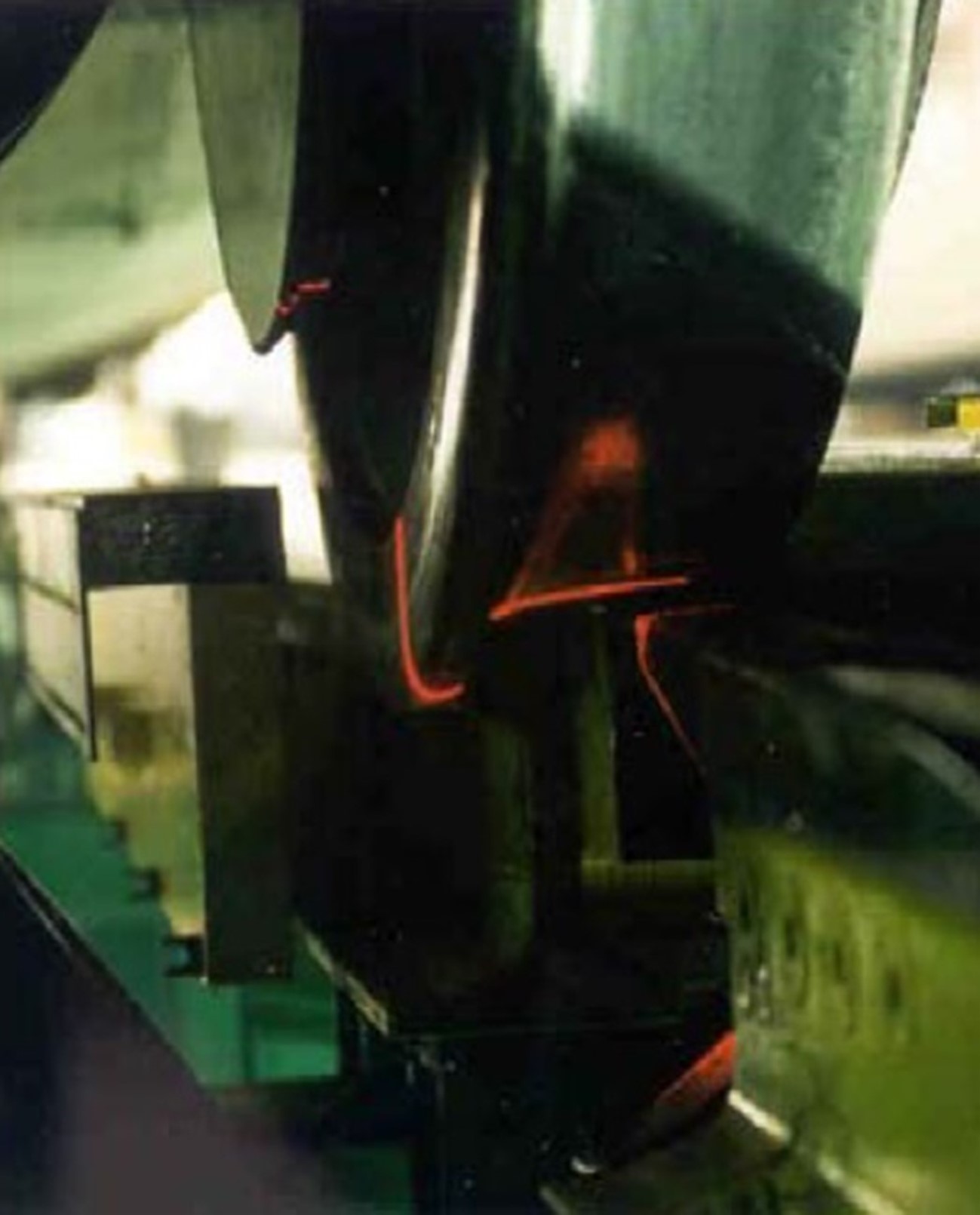

- Artificial Vision Wheelset Parameter Measuring Equipment (EVA): The parameters of all the wheels are measured while the train is running, automatically detecting any wheels that are out of tolerance. It is based on laser wheel illumination and special camera imaging.

- Wheelset Surface Defect Detection System (DSR): Thanks to an advanced ultrasound detection system, it identifies and quantifies any instant deterioration that may have occurred during circulation on the surface of the tread band (cracks, wheelflats, dents, etc.)

- Wheelset Eccentricity Measuring Equipment (EMO): This system measures irregular wear of the tire, that is to say, the lack of roundness. Throughout a complete turn of the wheel, the system monitors the roundness defects that occur on three wheelset circles (selected by the customer) by obtaining the wheel out of roundness value and the corresponding graph.

TECHNICAL CHARACTERISTICS | |

Running speed for measurement | 0-15 Km/h |

Max. running speed without measurement | 20 Km/h |

Measurement exactness | Standard deviation |

Flange height | ≤ 0.1 mm |

Flange thickness | ≤ 0.1 mm |

QR factor | ≤ 0.1 mm |

Calculated diameter | ≤ 0.1 mm |

TECHNICAL CHARACTERISTICS | |

Working standard frequency: | 1MHz |

Number of excitation pulses | Configurable |

Amplifiers gain of acquisition | Up to 80 DB |

Maximum number of signal samples | 31980 samples |

Standard reduction factor | 32 |

Defect detection depth | 4 mm |

Running speed for measurement | 0 – 10 Km/h |

Running speed without measurement | 20 km/h |

TECHNICAL CHARACTERISTICS |

Running speed through the installation during the measurement process: up to 10km/h |

Measurements can be made at variable speeds: no need to maintain a constant speed |

There is no physical contact with the wheel |